Services and Activities Expert support to make your project a success

Coating Process Integration

EPI supplies equipment of “pre-treatment – coating” intended for automobile, railroad, aeronautics, and capital goods manufacturers:

- Pre-treatment tunnel

- Electro-dip

- Sealer

- Painting booth

- Curing oven

- Conveyor systems

- VOC abatement

According to your needs, EPI can provide all supply and services for the project:

- Design

- Manufacturing

- Installation

- Commissioning

Assembly process

In recent years, EPI has been developing its activity in the sector assembly process. EPI offers type facilities:

- Paint touch-up booth

- Preparation box

- Watertest

- Robotic box

Industrial ventilation

For more than 20 years, EPI accompanies, the heavy industries by working in the energy and industrial ventilation domain, in Europe and Worldwide. For your process and/or ventilation line EPI can provide advice, improvement and/or new equipment.

Environment – COV

Environment is one of the key preoccupations of the industrial world.

- Liquid effluents: EPI modernises pre-treatment by the replacement of phosphate stages by zirconium conversion.

- Gaseous effluents – Volatile Organic Components: EPI installs recuperative or regenerative oxidisers (RTO).

Lead Contractor

Equipment Creation / Modification:

- Sheet metal work.

- Metal work.

- Automation.

- Electrification.

- Hydraulics.

- Aeraulics.

- Thermal.

- Work ergonomics.

- Conveyor systems.

The client will only deal with EPI who guarantees the performance of all sub-contractors under their responsibility.

Engineering

Relying on their savoir-faire, EPI mobilizes the means and expertise necessary for the development and optimization of your processes.

EPI is your partner and can be part of your projects as advisor or design office. EPI performs technical audits of your workshops and of your equipment to be able to submit long-listing iprovements:

Productivity:

- Fabrication cost

- Overall Equipment Effectiveness (OEE)

Technology:

- Energy assessment

- Obsolescence of equipment

- Incorporation of new data: change of production and incorporation of new regulations

-

-

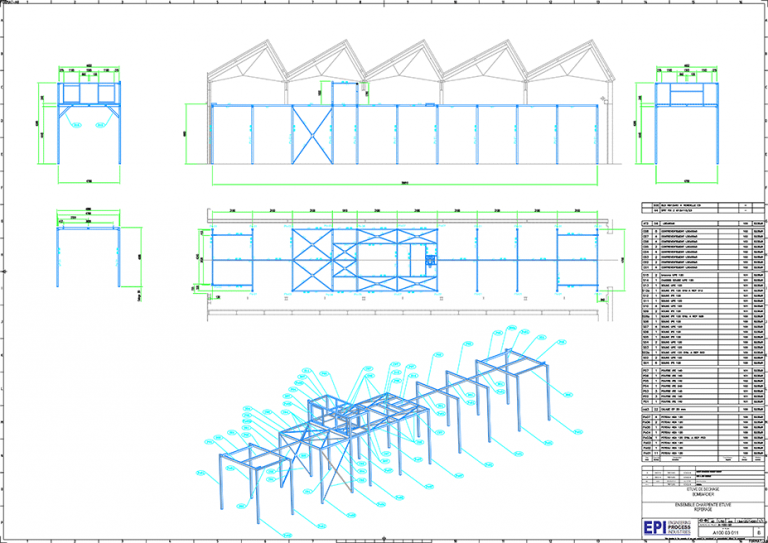

The experience and savoir-faire of our employees, in all project phases, allows us to deal with the diverse aspects of engineering:

- New process layouts.

- 2D – 3D survey and design office.

- Audit and evaluation of existing equipment.

- Proposals of improvement with equipment proposal and overall cost of operation.

- Consulting in Russian workshop.

- Computer assisted maintenance software.

Installation certifications

Labour Law

Labour Law- NFT 35009 standard

- NF EN 12215 standard

- NF EN 13355 standard

- Other…

Other

- X-Ray Room

- Equipment dismantling

- Industrial equipement moving